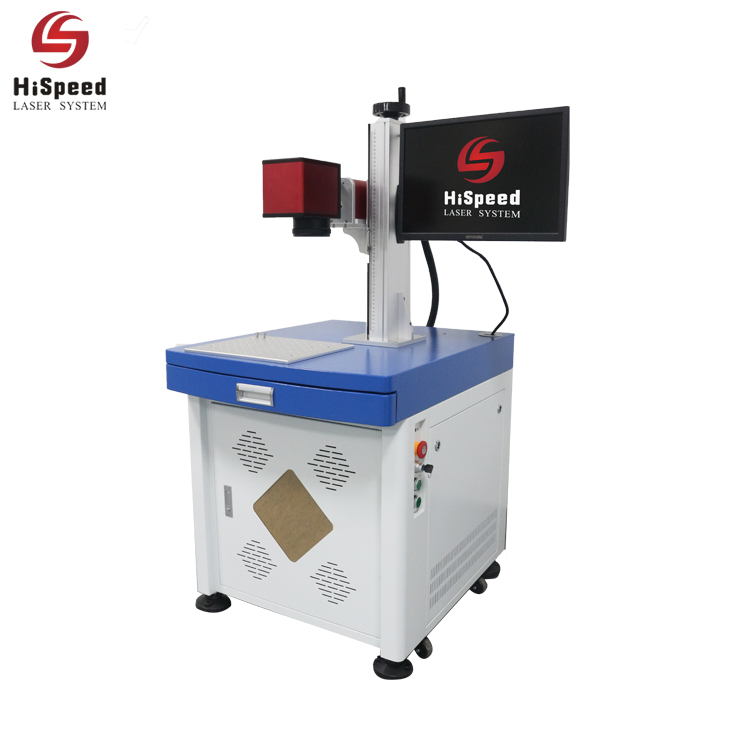

QCW Battery Fiber Laser Welding Machine

The galvanometer scanning laser welding machine welds up to 2000 lugs per hour at 1–20 points per second, making it ideal for high-speed spot welding of ultra-thin stainless steel components like mobile phone shields, battery lugs, and metal casings.

Key Features

Capable of welding up to 2000 lugs per hour with a speed of 1–20 points per second for high efficiency.

Ideal for high-speed spot welding of sheet metal materials like copper foil, stainless steel, and nickel plates.

Suitable for welding batteries, mobile phone shields, housings, capacitor shells, hard disks, micromotors, and sensors.

Supports multi-channel output with time-sharing or energy-sharing modes to match various production needs.

Can be integrated with assembly lines to improve automation and overall welding efficiency.

Technical Specifications

| Laser Power | QCW-75 (Peak Power: 750W) / QCW-150 (Peak Power: 1500W) |

| Laser Type | QCW fiber laser source |

| Wavelength | 1064nm |

| Max Welding Thickness | 0.1–2.0mm |

| Gross Power | ≤13KW |

| Voltage | 220V ±10% / 50Hz / 30A |

| Pulse Width | 0.3–20ms |

| Frequency | 1–100Hz |

| Spot Adjustable Range | 0.2–2mm |

| Positioning | Red Indicator |

| Repeatability | ±0.01mm |

| Control System | PLC or PC (CNC2000) |

| Working Area | 200mm × 200mm × 200mm |

Applications