XD Q

The CAB XDQ is a professional dual-sided thermal transfer printer designed for double-sided printing in a single pass cab XC Q Two-Color Label Printer - Computype, featuring dual print heads with independent heating control and dual resolution capabilities (300/600 dpi)

Key Features

Print resolution 300 dpi if printing as wide as 105.7 mm

Print resolution 600 dpi if printing no more than 54.1 mm wide using DR4-M60 print roller

Heating can be assigned separately to each print head

If printing only on top of material using print head 2, print head 1 is automatically lifted and ribbon stopped

Guiding materials in centered position for precise print images with slim continuous materials

Automated ribbon saving provided on print head 1 when printing on bottom of material

Continuous print images when cutting or perforating labels at no backfeed

Optimized printing enables multiple print jobs to be printed seamlessly without loss of labels

CSQ cutters and PSQ perforation cutters available

A separator is part of the chassis - separates continuous material reliably from ribbon

Steel transport roller standard for textile materials, rubber option with shrink tubes available

Transport roller can be pivoted for material changeover

Technical Specifications

| Label printer | XD Q4/300 / XD Q4.2/600 |

| Printable resolution | 300 dpi / 600 dpi |

| Print speed max | 150 mm/s / 100 mm/s |

| Print width max | 105.7 mm / 54.1 mm |

| Width of a material | 114 mm |

Consumables & Accessories

Labels

Compatible thermal transfer and direct thermal labels for precision printing

Ribbons

High-quality thermal transfer ribbons for accurate print images

cutters

Paper, cardboard, textile and synthetic materials can be cut resp. perforated, so can shrink tubes, continuous or ready for use.

External ER4, power supply built in

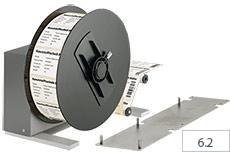

Label webs may be wound outside or inside. They are wound consistently and tight by electronic control, with a pendulum arm.

ST400 M stacker providing a cutter

Printed materials can be cut and then collected. Print jobs stop if the maximum number of labels have been collected. Limitations may occur with stiff or curved materials. cab recommends to have such operations tested.